Automotive Sonic Testing

Measuring the wall thickness of automotive cylinder bores, head ports and other components can be vital for quality control in manufacturing or in a boring process where a minimum thickness must be maintained. Cast aluminium or steel engine blocks can be difficult to inspect with complex geometry and limited access. Ultrasonic thickness gauging allows for these measurements to be performed. With dedicated probes that are contoured to the shape of the cylinder or pencil probes to access tight spaces, high accuracy thickness can be measured.

Measuring the wall thickness of automotive cylinder bores, head ports and other components can be vital for quality control in manufacturing or in a boring process where a minimum thickness must be maintained. Cast aluminium or steel engine blocks can be difficult to inspect with complex geometry and limited access. Ultrasonic thickness gauging allows for these measurements to be performed. With dedicated probes that are contoured to the shape of the cylinder or pencil probes to access tight spaces, high accuracy thickness can be measured.

Introduced to the market in 2015, the latest NovaScope 6000 incorporates the proven, traditional features which customers came to appreciate and rely on throughout the instrument’s generations. In addition, new capabilities have been designed which offer advanced possibilities to fine-tune and customize measurement setups. The instrument is loaded with a series of parameters and adjustment options to make literally any conventional UT probe from any manufacturer work at its best. From a handling perspective, it also became battery-operated as well as lighter than ever before.

Applications:

- High resolution turbine blade inspection

- Thickness measurements on investment wax castings

- Bond inspection on multi-layer composites

- Metals, plastics, composites, glass, rubber

- Corrosion, erosion, chemical-milled inspections

High Speed Digital Image Correlation (DIC) for Vibration and Modal Shape Analysis

For today’s high demands for highest reliability, durability and environmental performance of machines, electronics and mechanical components, static stress-strain measurements are not sufficient. Dynamic measurements are necessary and Vibration Analysis (VA) has subsequently found widespread use.

For today’s high demands for highest reliability, durability and environmental performance of machines, electronics and mechanical components, static stress-strain measurements are not sufficient. Dynamic measurements are necessary and Vibration Analysis (VA) has subsequently found widespread use.

Vibration can be desirable – for example, the motion of the wooden body of a violin, a mobile phone vibrator, the cone of a loudspeaker or the vibration of buildings during an earthquake.

In many situations, however, vibration is undesirable because of wasted energy, fatigue symptoms or the creation of unwanted sound. For instance, the vibrational motions of engines, electric motors, electronics or any mechanical device in operation are typically undesired. Such vibrations can be caused by imbalances in the rotating parts, uneven friction, the meshing of gear teeth, material design flaws and more. Careful designs usually minimize these vibrations. Experimental vibration measurements are typically used to validate analytical models or when the theoretical models are inaccurate.

Experimental Finite Element Method (FEM) validation using Digital Image Correlation (DIC)

A variety of mechanical engineering disciplines, such as aeronautical, biomechanical, and automotive industries, rely on Finite Element Method (FEM) in the design, development, and testing of their products. State-of-the-art FEM software packages include specific modules to simulate and investigate, among others, thermal, electromagnetic, fluid, and structural behaviours and phenomena.

A variety of mechanical engineering disciplines, such as aeronautical, biomechanical, and automotive industries, rely on Finite Element Method (FEM) in the design, development, and testing of their products. State-of-the-art FEM software packages include specific modules to simulate and investigate, among others, thermal, electromagnetic, fluid, and structural behaviours and phenomena.

In spite of the significant advances that have been made in FEM, the results obtained from any FEM study are purely theoretical and must be carefully examined before they can be used. Qualifying the outcome of a FEM simulation typically raises questions or issues such as:

- Is the level of modelling and simplification sufficient for the required application?

- What are the most critical parameters in the simulation?

- Up to which degree do the simulation results reflect reality?

Finding answers to these questions involves a thorough validation of FEM results. A common way of validating the quality and correctness of the computational models is the comparison with full-field 3-dimensional experimental data measured by Digital Image Correlation (DIC).

Particle Image Velocimetry (PIV) for Automotive Industry

PIV is a whole-flow-field measurement technique for measuring instantaneous two or three components of velocity in a variety of flows. The application of PIV in research and industry is widespread, due to its ease of use and accurate data representation. As easy and intuitive as PIV is, it involves many cross-disciplinary challenges, from classical optics and imaging to the use of dedicated state-of-the-art digital electronics and lasers.

Examples of PIV Applications in Automotive Industry:

i) Flow field mapping around a full-scale car

ii) Air/Fuel mixture formation analysis in vehicle engine

iii) Study of soot particle generation

iv) Air flow study around and inside vehicles

v) Indoor Climate Flow Visualization

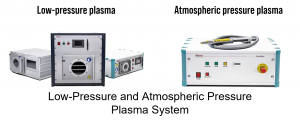

Plasma Surface Treatment for Automotive Industry

Plasma applications have become indispensable in car manufacturing. Coordinated processes are a prerequisite for consistently high quality of the products. Our systems meet the requirements of pretreatment technology in automotive construction, such as removal of manufacturing or silicone residues by means of plasma cleaning. Plasma activation can be used as a pretreatment before gluing or painting; another option is plasma etching of high-performance plastics and the application of a plasma coat as adhesion promoter (plasma primer).

Frequent applications of plasma in automotive engineering:

i) Flock coating on the glove compartment

ii) Increase of surface energy of plastic components before painting

iii) Prevention of dirt accumulation on vehicles components

iv) Rustproof coating

v) Surface activation of gasket before gluing

vi) PWIS-free cleaning

vii) Surfaces activation & cleaning before casting/bonding/gluing/installation in cars