Stability studies are performed in life sciences, chemical, and food and beverage industries to determine the effects of environmental conditions on product quality. Stability studies provide the supporting data that companies use to establish product storage requirements and expiration dating.

Stability test chambers are enclosures that are used to detect the effects of pre-specified circumstances on biological materials, industrial materials as well as on electronic components. These chambers are used to detect humidity and temperature ranges. Stability chamber are used to perform stability studies.

In the pharmaceutical, drug stability testing are being conducted. Drug stability means the ability of the pharmaceutical dosage form to maintain the physical, chemical, therapeutic and microbial properties during the time of storage and usage by the patient. It is measured by the rate of changes that take place in the pharmaceutical dosage forms.

ICH Q1A – STABILITY TESTING OF NEW DRUG SUBSTANCES AND PRODUCTS

ICH Q1B Option 2 – PHOTOSTABILITY TESTING OF NEW ACTIVE SUBSTANCES AND MEDICINAL PRODUCTS

FDA 21 CFR Part 11 – Electronic Records; Electronic Signatures – Scope and Application

World Health Organization

CPMP – PHOTOSTABILITY TESTING OF NEW ACTIVE SUBSTANCES AND MEDICINAL PRODUCTS

Long Term Stability Testing Chamber Large Volume

Long Term Stability Testing Chamber Large Volume

Long Term Stability Testing Walk In Chamber

Explosion-proof heating and drying ovens for manufacturing sectors, such as the chemical, pharmaceutical and electronics industries, often require heating and drying ovens in which flammable materials, such as solvents, gases etc., can be placed in almost unlimited amounts. These materials may form an explosive mixture in combination with air.

CE compliant design as per 2014/34/EU.

Group IIA – Atmospheres containing propane, or gases and vapors of equivalent hazard. and

Group IIB – Atmospheres containing ethylene, or gases and vapors of equivalent hazard.

Ovens for Various application including Ex-Proof

Testing to stabilise and optimise the quality of products are indispensable in research and laboratories. Our laboratory test chambers were designed for this purpose and allow reproducible temperature and climatic tests directly at the workplace. A high temperature range from -70°C to +180°C as well as high-quality processing and construction are crucial for reliable measurement results –compliance with test standards such as Various climatic zones can be simulated with temperature ranges between +10°C and +95°C, and humidity ranges between 10% RH and 95% RH.

Standards: DIN, ISO, MIL, IEC, DEF (DEFENCE), ASTM.

Small sample Climatic Chamber with Temperature Humidity control

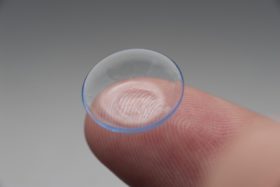

Oxygen permeability (OP) is a parameter of a contact lens that expresses the ability of the lens to let oxygen reach the eye by diffusion. In soft contact lenses, it is dependent on the thickness of the lens and the material of the lens, especially concerning the water content.

Application

The importance of oxygen to the health of the cornea is well known; as a result contact lens users will prefer a product with proven high oxygen performance. Lens manufacturers advertise their various product specifications, including oxygen permeability and transmission, usually to Eye Care Professionals who can then advise patients on the most suitable choices for their particular needs. The permeability is referred to as Dk and the transmission Dk/t. These properties are derived from:

D – the material diffusion coefficient k –

K – the oxygen solubility t –

t – the lens thickness

A given lens material, typically a hydrogel, will absorb an amount of oxygen governed by its k value, while a higher D will ensure rapid movement through the lens. The thicker the lens the further oxygen has to travel consequently reducing its transmission.

A contact lens design using a particular material will require its oxygen transmission measured. Higher permeability materials will perform better, together with thinner lenses, but simply choosing the highest Dk material and making thin lenses is not an easy option, as will be explained later. The lens shape and thickness varies with prescription, a focal length of –3.00 Dioptres has been chosen as the standard for oxygen transmission measurement. The thickness in the central region of the lens is used because this covers the most critical area of the cornea.

Types of lenses used today

Conventional hydrogel soft lenses contain a high proportion of water which provides the main path for oxygen diffusion. So for these products the Dk value is directly proportional to the water content of the particular hydrogel used. However the highest Dk materials are difficult to manufacture into thin lenses, resulting in a range of designs, some medium Dk thinner varieties, and other higher Dk thicker ones. The aim is to produce the highest Dk/t to maximise corneal oxygenation, commensurate with comfort and visual performance. The latest silicone hydrogels do not have their oxygen permeability governed by water content alone, but also by their constituent siloxane groups. Contact lenses containing these products are some of the highest performing available today, with very high oxygen transport and the highest levels of comfort.

Rigid gas permeable (RGP) contact lenses are still an attractive alternative to the soft varieties and probably offer better optical performance generally, combined with excellent corneal care. Although initially less comfortable than soft lenses, the Dk values for the RGP polymer materials are on a par with the best silicone hydrogels whilst offering much longer lifetimes with lower long term cost.

Measurement Standards

In the early days of contact lens use, indeed up to the early 1980’s the importance of corneal oxygenation was not well understood. However since that time international standards have been put in place to enable reliable oxygen permeation testing of lens materials. Early ISO standards 9913-1:1996 and 9913-2:2000 were put in place for polarographic (Fatt method) and coulometric determination of oxygen permeation through all types of contact lenses. However the high Dk Silicone based lenses proved difficult to measure accurately using these standards, in part due to lens dehydration during coulometric procedures. These standards have now been withdrawn and both replaced by ISO 18369-4:2006, which like the previous standards describes the measurement of Dk/t for finished lenses rather than a material sample. This oxygen transmission value is subsequently converted into the Dk value by measuring the lens thickness, t.

Solutions from Systech Illinois

Systech Illinois produce the 8000 range of oxygen permeation analysers, which are capable of measuring contact lens oxygen throughput. Utilising our proprietary coulometric sensor technology to detect oxygen transmission rates, samples are clamped or attached to a diffusion chamber, illustrated in the principle. Pure oxygen (99.9%) is then introduced into the upper half of the chamber while an oxygen-free carrier gas flows through the lower half.

Molecules of oxygen diffusing through the sample into the lower chamber are conveyed to the sensor by the carrier gas. This allows a direct measurement of the oxygen without using complex extrapolations. Oxygen transmission rate of the test sample is displayed as Dk.

In summary, it is possible to utilise Systech’s permeation analysers both for the development of new contact lens materials and also for certifying the finished products to the ISO standards. This will ensure trusted product data to instil confidence in professional and consumer alike.

Contact Lense Permeation Performance Testing

Testing process of sample with

permeation analyzer

Oxygen Permeation System

Application:

Monitoring workplace exposure limits in and around

sterilization facilities

Analyzer

The Series 8900 Ethylene Oxide Analyzer combines the selectivity of gas chromatography with the sensitivity of a Photoionization Detector (PID) providing interference free response to Ethylene Oxide (EtO) at levels below 0.05 ppm. This analytical method is referenced in OSHA’s “Occupational Exposure to Ethylene Oxide: Final Standard” 29 CFR Part 1910.

The system documents exposure levels including: time-weighted averages (TWA), short-term exposure limits (STEL) and instantaneous alarms. Areas that are typically monitored include; EtO Sources – gas storage areas, sterilizer doors, aeration doors, and the General Work Area – decontamination, packaging and preparation and sterile product storage areas.

The 8900 EtO Analyzer uses a dual column configuration with timed backflush to vent which is used to strip off moisture and heavier hydrocarbons. At sample injection a fixed sample volume is carried to the pre-cut column. Backflush of the pre-cut column is timed from sample injection so that only EtO and other similar compontents are eluted from the pre-cut column to the analytical column. Contaminates on the precut column are then vented. EtO is separated from potentially interfering components on the analytical column and elutes to the photoionization detector (PID) and/or flame ionization detector (FID) for analysis.

Features

• Direct measurement of Ethylene Oxide & Propylene Oxide

• Interference free response

• Automatic baseline adjustment for long-term stability

• Automatic calibration to a known EtO standard

• Reports exposure levels, TWA, STEL, and instantaneous alarms

• Analog output ranges are user selectable

• Graphic display of current or historical concentrations

• Multipoint sampling options

• RS-232 and optional LAN

Analysis Time: Detector: PID (FID or High-sensitivity PID Optional)

Column: Packed

Oven Temperature: 100 °C, Nominal

Carrier Gas: Nitrogen, 32 cc/min, Nominal

Lower Detection Limit: <0.05ppm

Accuracy: 1% @ 1ppm

Precision: 2% of Measured Value

Span Drift (24HR): <2% of Full-scale

Sample Flow Rate: 250-500cc/min, typical

Output:

Analog: (1) 0-20ma or 4-20ma loop power supplied,

isolated. Selectable for: gas concentration, unintegrated detector signal. Options for up to 20 additional programmable 0-20ma, 4-20ma or voltage outputs: 0-1V, 0-5V, or 0-10V.

Digital: RS-232, optional Local Area Network

Relays: (5) User programmable relays for concentration and diagnostic alarms (1A @ 30Vdc). Options for up to 32 additional relays available.

Inputs: Optional digital input board for 3 contact closure inputs. Supports start analysis, start calibration, and analyze calibration gas sample.

Sample data from the analysis

Sample data from the analysis

The autoclave carries out its exact function of sterilizing materials. It is a machine that uses pressure and steam to reach and maintain a temperature that is too high for any microorganisms or their spores to live. Microorganisms are what most people commonly refer to as germs.

Many laboratories rely on steam sterilizers or equipment where processes are monitored using pressure and temperature control.

Sterilization that is easy, safe, accurate, reproducible and validatable.

The sterilization process in an autoclave can be rather difficult.

The necessity to qualify an autoclave and to validate the sterilization process comes from, among other things, the Medicines Act, the Medical Devices Act, the Chemicals Act, and the Ordinance on the Protection of Biological Substances and Genetic Engineering. These laws and regulations sometimes refer to directives, rulings, or decisions of the commission, guidelines, and standards. By referring legally binding EU regulations to legally non-binding standards or guidelines such as the EU-GxP guidelines for

– Good Manufacturing Practice (GMP)

– Good Clinical Practice (GCP)

– Good Laboratory Practice (GLP)

they are given a law-like character and their compliance is checked and periodically controlled by government agencies. The aim is to ensure and guarantee a high and above all uniform quality standard.

Vertical Floor Standing Autoclave

Horizontal Floor Standing Autoclave

Horizontal Bench Top Autoclave

A universal testing machine (UTM), also known as a universal tester, materials testing machine or materials test frame, is used to determine the tensile strength and compressive strength of materials. The “universal” part of the name reflects that it can perform many standard tensile and compression tests on materials, components, and structures (in other words, that it is versatile).

The set-up and usage are detailed in a test method, often published by a standards organization. This specifies the sample preparation, fixturing, gauge length, analysis, etc.

The specimen is placed in the machine between the grips and an extensometer, if required, can automatically record the change in the gauge length of the specimen during the test. If an extensometer is not fitted, the machine itself can record the displacement between the grips on which the specimen is held.

Once the machine is started it begins to apply an increasing load on specimen. Throughout the tests the control system and its associated software record the load and extension or compression of the specimen.

The UTM can be equipped with accessories that are designed for biomedical applications, such as fluid baths, light-weight grips and fixtures, and non-contact strain measuring instruments.

Bio-mechanical Testing

Scissors Action Grips

A dynamic testing machine will be required for dynamic testing applications. One example of such a machine is an electro-dynamic tester, which utilizes an electric actuator to apply a varying force over a period of time.

Other than determining the fatigue life of a material or component, these testing machines can also be used to characterize the dynamic properties of materials, such as those used in biomedical implants and tissue engineering applications.

Multi-axial models of the dynamic testing machines can be used to create test solutions for virtually any application, from complex kinematics research and trauma studies to detailed evaluations of implantable devices for the spine, knee, hip or other areas of the musculoskeletal system.

Being electrically driven, both the UTM and the electro-dynamic tester are clean and quiet, and are thus suitable for use in biomedical laboratories

Standards

ISO – 14801, 6475, 7206, 14879, 1099, 7800, 5835/6475, 80369-1, 6721-4, 6721-5, 6892.

ASTM – F1717, F2077, F543, F1800, F3140-17, E606, D3479, E466, A938, D1043, D5279, F383

Individual Device Fracture in Multi-Sample Tests

Sequential Injection technology is ideally suited for on-line process monitoring. Our Process Analyzer provides a Sequential Injection instrument in a robust, industrial-grade package. Owing to the unique capabilities of the Sequential Injection liquid handling technology and the intuitive control software package, it has been successfully utilized for continuous process measurements in medical and pharmaceutical industry.

Online Process Analyzer:

- Programmable dilution

- Ability to handle thick-flowing liquids with high precision

- Colorimetric detection, ranging from very dilute to intensely colored solutions

- unit operation of heating

- unit operation of solid-phase extraction

- unit operations of dialysis or gas diffusion

We offer multiple applications critical to the Process Analytical Technology (PAT) initiative that is rapidly gaining ground among biopharmaceutical manufacturers.

- Automated aseptic sampling from bioreactors

- Peptide mapping

- Amino Acid analysis

- Sialic Acid monitoring

- Glycan Profiling

Online Process Analyzer

The manufacturing processes in medical engineering must meet the most demanding standards. Surfaces must not only be clean but perfectly flawless and/or sterile. All our systems are equipped with a USB and LAN connection to ensure traceability of pretreatment process by way of printed-out process records. Since we are certified to DIN EN 13485, we meet all the specified requirements in the quality management system that apply when a company must submit proof of its ability to deliver medicinal devices and the respective services.

We also offer this process as surface treatment services provided on our premises. Our class 8 clean-room is certified to DIN ISO 14644. Thus, we can ensure optimum surface quality of your components and parts.

Frequent applications of plasma in automotive engineering:

i) Implant infection prevention using plasma treatment

ii) Integration of joint and dental implants into human body

iii) Plasma polymerization treatment of stent

iv) Surface hydrophobing

v) MEMS hydrophiling via plasma polymerization

vi) Microfluidic chip activation before bonding

vii) Barrier/HMDSO coating of lenses