Specific heat is a measure of how much heat energy is required to raise the temperature of a material. Specific heat usually refers to a property an element or a single type of material. A lithium-ion battery is a composite construction containing aluminium, copper and many other materials. As such, it does not have a “specific” heat capacity, but an average specific heat influenced by the specific heats of each material that goes to make up the cell.

Heat capacity testing of batteries is aiming to establish a previously unknown quantity. Literature values available for specific heat capacity are those of the chemical elements or common materials such as plastics. The battery is a composite object made up of many different materials in different amounts which vary from one type of battery to another. Specific heat refers to a chemically homogenous material. The battery is not homogenous and so when this parameter is used to characterize batteries is called the average specific heat.

Isothermal Battery Calorimeter Cell Format: Cylindrical

Isothermal Battery Calorimeter Cell Format: Cylindrical

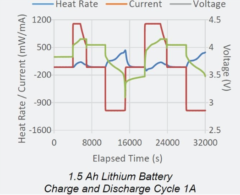

The main application of the isothermal battery calorimeter is accurate and easy testing of heat output from charging and

discharging a single battery. Lithium-ion covers a range of

battery chemistries which involve the flow of lithium ions from the anode to the cathode. Lithium-ion is typically a secondary cell technology, meaning that the lithium-ion batteries are rechargeable.

Heat changes occur during the charging and discharging of batteries is mainly due to their internal impedance. Energy lost as heat cannot be used as useful electrical energy so it is important to minimize the heat produced by cells during use. Companies utilizing batteries need to quantify this heat so adequate cooling can be added if required.

The IBC allows custom charge/discharge cycles to be carried out with ease using the in-built cycler in combination with the control software. The calorimeter is isothermal and heat is removed or added to the cell using a Peltier heater. This works by using power compensation to keep the temperature inside the chamber constant. Heat flow to and from the Peltier is recorded with the software and can be used to give information about battery performance and parameters.

Isothermal Battery Calorimeter Cell Format: Prismatic

Isothermal Battery Calorimeter Cell Format: Prismatic

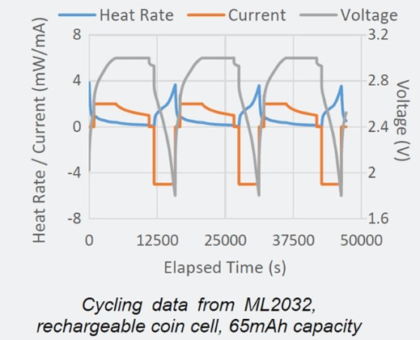

Charging and discharging of a electrical cell is not a completely efficient process. The transfer of current in general, whether it is into or out of a cell, through pylons or around the home results in the conversion of electrical energy into thermal energy due to the resistance of wires and other components.

Cell manufacturers have a requirement to quantify the energy loss due to internal resistance. Quantitative analysis of the electrical energy loss and the heat energy production from a cell during operation is not simple. The internal resistance of the cell comes from both the internal electrical resistance as well as the ionic resistance, which is due to the resistance from the chemical process taking place inside the cell in which lithium ions move from the cathode to the anode or vice versa in order to remove of deposit charge from or into the cell. In addition, heat output from the cell will varying (non-linearly) depending on the rate of current being drawn or applied. Internal resistance is also a variable property which increases with the temperature of the battery. In this way, from knowledge of heat change, the efficiency of the cell can be determined with IBC testing, heat change and electrical energy change.

Isothermal Battery Calorimeter Cell Format: Coin Cell

Isothermal Battery Calorimeter Cell Format: Coin Cell

Our full range of products— from Cycle Life Testers for R&D of multiple chemistries and applications to High Rate Discharge testers for cold crank testing—are configurable for testing to industry standards such as IEC, SAE, BCI and drive simulations for FUDS, SFUDS, GSFUDS, DST and ECE-15L. Additional standard product offerings for battery development and testing, as well as custom engineering services, offer our clients maximum control over every aspect of their testing protocols and methods.

From Life Cycle Testing for cells, modules and packs to Drive Simulation for EVs, our state-of-the-art laboratory testing and charging equipment is vital to any battery lab.

Additional applications include

- Charge / Discharge testing

- Cold crank testing

- Reserve capacity testing

- Start / Stop testing

- Supercap / Ultracap testin

Lab-Scale Battery Testing

Battery Cell Tester

Temperature Controlled Water Bath

Constant Current Charging System

High Current Discharge Testing System

High Voltage Pack Testing System

We offer customers an extensive line of products designed to address the specific requirements of every battery application and chemistry in use today. Fifty years of progressive, innovative engineering have resulted in the reliable, high performing, flexible designs that have set quality standards for the entire industry.

Product offerings include designs for container formation for stationary industrial VRLA batteries and water bath formation featuring polarity reversal for tackless formation of automotive and industrial plates.

Our equipment supports

- Automotive/SLI

- Stationary & industrial VRLA

- Tackless plate formation

- High rate, production & end-of-line testing

- Acid recirculation

Manufacturing-Scale Battery Testing

High Voltage Charge/Discharge Formation

Constant Current Formation Charger

High Voltage Formation Charger

High Rate Discharge Battery Testing System

End of Line Testing System

- Power and energy efficiency analysis

- DC and AC impedance testing

- Long-term measurement for durability or life time analysis (cycle simulation, power cycling, charge and discharge rate, self-discharge, fast charge)

- Ambient influences (temperature)

- Charging station test

- Overall system test in the complete drivetrain including electric drive and simulated loads (testing of functionality, power, efficiency, range, reverse load feedback—regenerative braking)

- Fault testing (overload, short-circuit, overheat, mechanical load, defect)

- Battery thermal management

- Battery management system test (overload protection)

- Dynamic load investigation (current ripple)

- Electric impedance spectroscopy

Energy Storage Testing

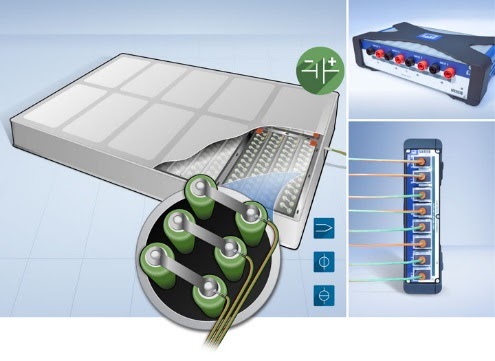

High-voltage measurements are time-consuming and cost-intensive. Therefore, security and efficiency were allocated highest priority in our isolation test instrumentation. You can unreservedly place your trust in the leading isolation system worldwide for precise transfer of your measurement signals to the data acquisition system:

- Secure data transmission in high-voltage environments thanks to fiber-optic isolation

- Worldwide use and proven a thousand times over – already in the 4th generation

- Cost-efficient transient recorder for applications with low channel counts

- Top-class measurement technology through optimal integration of hardware and software

Measurement Data Acquisition in High-Voltage Areas

Measurement Data Acquisition in High-Voltage Areas

A high voltage impulse happens when lightning strikes power lines on masts to cause an instantaneous surge of very high voltage. Although the high voltage impulse lasts only a split second it can damage insulation on any electrical equipment – such as transformers and switchgear – connected to the power line.

Damage from the high voltage impulse can result in the power grid experiencing a partial failure or blackout, leading to dissatisfied consumers and potentially high repair costs.

High voltage impulse tests on transformers, surge arrestors, isolators and switchgear ensure that these components can withstand the instantaneous electrical surge and continue to operate reliably.

The high voltage impulse caused by lightning can be of either positive or negative polarity. A standard high voltage impulse reaches peak voltage after about 1.2 μs and decays to 50% of this peak voltage about 50 μs after the beginning of the impulse.

Impulse Test with Transient Recorder

Measurement system using fiber optic isolated digitizers

Lightnig

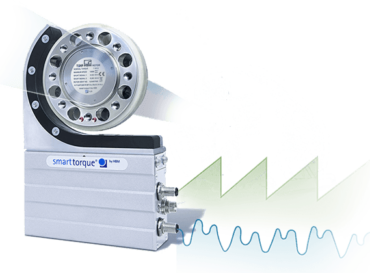

Torque is a vital mechanical measurement for the machine building industry, but this measurement is also relevant in some other applications. Precise torque measurement is required by many industries, one example is the users and manufacturers of test benches, for various tests.

There is also a requirement for modern engines to have improved mechanical performance by increasing their rotating speed, and improved accuracy in various areas including efficiency measurements. The demands on the efficiency of generators in all kinds of power plants are increasing dramatically.

Cost pressure and more stringent environmental regulations require knowledge of specific characteristic values reflecting the performance of your generators. We are the global market leader in torque measurement—and provides a range of powerful analog and digital torque transducers.

Torque Measurement System

Torque Measurement System

In wind energy there are versatile applications such as the monitoring of the wind load in the blades of wind turbines in order to increase reliability and availability of wind turbines. The same system can be used to protect the wind turbine from high winds by stopping the machine and turning the blades into a safe position.

Another example for applications in wind energy is power measurement. The mechanical power e.g. of generators needs to be measured accurately with high precision torque transducers according to the standard IEC 60034.

Optical Wind Blade Monitoring System

Component Tests in Wind Turbines

Data Acquisition Software

Condition Monitoring Systems for Offshore Wind Turbines

Apply precise, extremely high-force rotational and off-axis loading to wind turbine drive train and bearing systems to study their performance and durability characteristics under a full-spectrum of real-world operating conditions. Available in a range of capacities, these highly robust systems are deployed worldwide to help achieve critical improvements in wind turbine reliability.

Applications:

- Performance Under Load

- Static Deflection and Stiffness Measurement

- Durability

- System Simulation and Verification

Test Specimens

- Nacelle Assemblies

- Drivetrain Systems

- Drivetrain Components

- Main Bearing Systems

- Yaw Bearing Systems

Test Standards: International Electrotechnical Commission Technical Specification 61400-23

Non-Torque Loading (NTL) Systems